Creating Improved Outcomes for Patients, Staff and the Community

Healthy Building Solutions for a Critical IndustryUncompromising Healthcare Solutions From YORK®

Optimized performance, resiliency and cost-savings to meet mission-critical goals

Hospitals and healthcare facilities are being faced with unprecedented challenges, including new, local legislation. That’s why the portfolio of YORK® solutions spans the full range of tonnages and capacities – precisely meeting the needs of every facility and every mission-critical application.

From more efficient water use and innovative heat recovery options to advanced connectivity and globally proven reliability, healthcare solutions from YORK® are consistently among the most future-focused, most sustainable solutions available.

We partner with some of the most demanding facilities on the planet to lower risk and increase peace of mind. From remote monitoring to predictive and diagnostic services, we help optimize healthcare operations with industry-leading expertise and data-driven planning.

Featured Products

YORK® YVWH-200 Water-to-Water Variable Speed Dual Screw Heat Pump

4,050 MBH (1,186 kW) heating, 200 tons (703 kW) cooling

With up to 25% lower annual energy costs and up to 30% less water consumed when compared to a conventional chiller and boiler system, the YORK® YVWH-200 Water-to-Water Variable Speed Dual Screw Heat Pump can deliver an ROI for healthcare facilities in as few as 3 years. Engineered as a practical, high-temperature-water-heating heat pump solution to help make the transition from fossil fuel-burning boilers, the YVWH is the first screw heat pump that can provide hot water temperatures up to 176 °F (80 °C) while simultaneously providing chilled water @ 41 °F (5 °C).

Additional Benefits

- Delivers up to 176 °F (80 °C) water temps – the highest of any screw heat pump on the market

- 3-mode operation: heating only, cooling only or simultaneous heating and cooling

- Turndown: 25% of design capacity made possible through VSD and compressor VI control technologies

- Significant carbon savings translate to an annual CO2 emissions reduced by approximately 20% (approx. 4,000 metric tons per year)

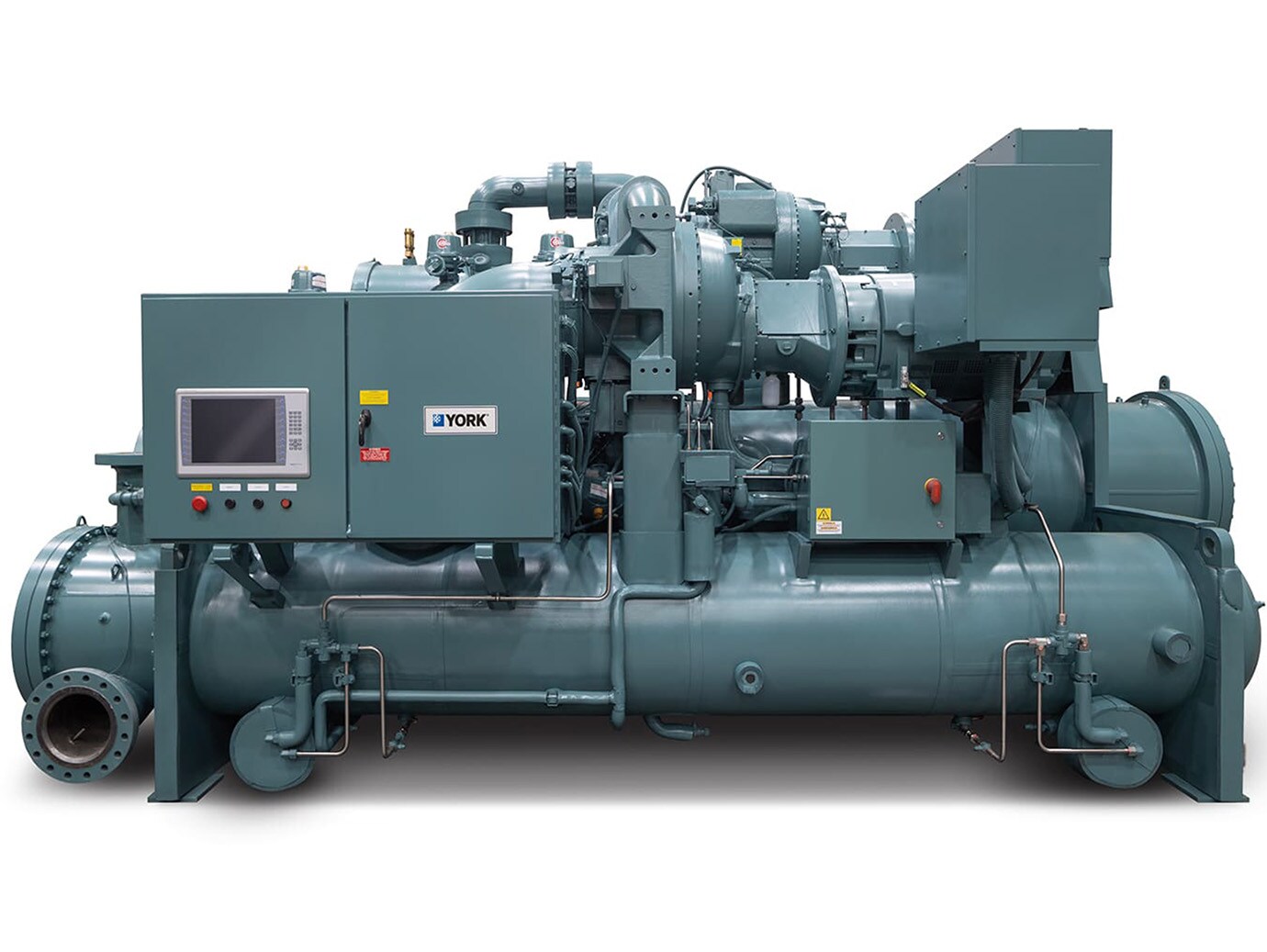

YORK® CYK Water-to-Water Compound Centrifugal Chiller/Heat Pump

7,000-38,000 MBH (2,051-11,136 kW) heating, 400-2,000 ton (1,406-7,033 kW) cooling

Designed to help jump-start the path to decarbonization in buildings with lesser heating and cooling loads, the YORK® CYK Water-to-Water Compound Centrifugal Chiller/Heat Pump helps turn the corner from fossil fuel-burning boilers in healthcare facilities with stand-alone heating and cooling needs through electrification. In fact, the CYK Compound Centrifugal Heat Pump is the ideal, high-efficiency electric heating solution for HVAC systems with the capability of delivering high-temperature hot water as high as 170 °F (77 °C).

Additional Benefits

- Two electric motor-driven centrifugal compressors deliver simultaneous hot water and chilled water @ 42 °F (5 °C) / 170 °F (77 °C)

- Two-compressor design also provides unique adaptability, with each compressor capable of being optimized to match specific operating conditions and requirements

- Designed specifically for high-head conditions, the YORK® CYK heat pump delivers high-temperature water with superior efficiency

- Compressors and motors mounted above the shells for a compact footprint

- Patented OptiSoundTM Control for reduction in operational sound levels

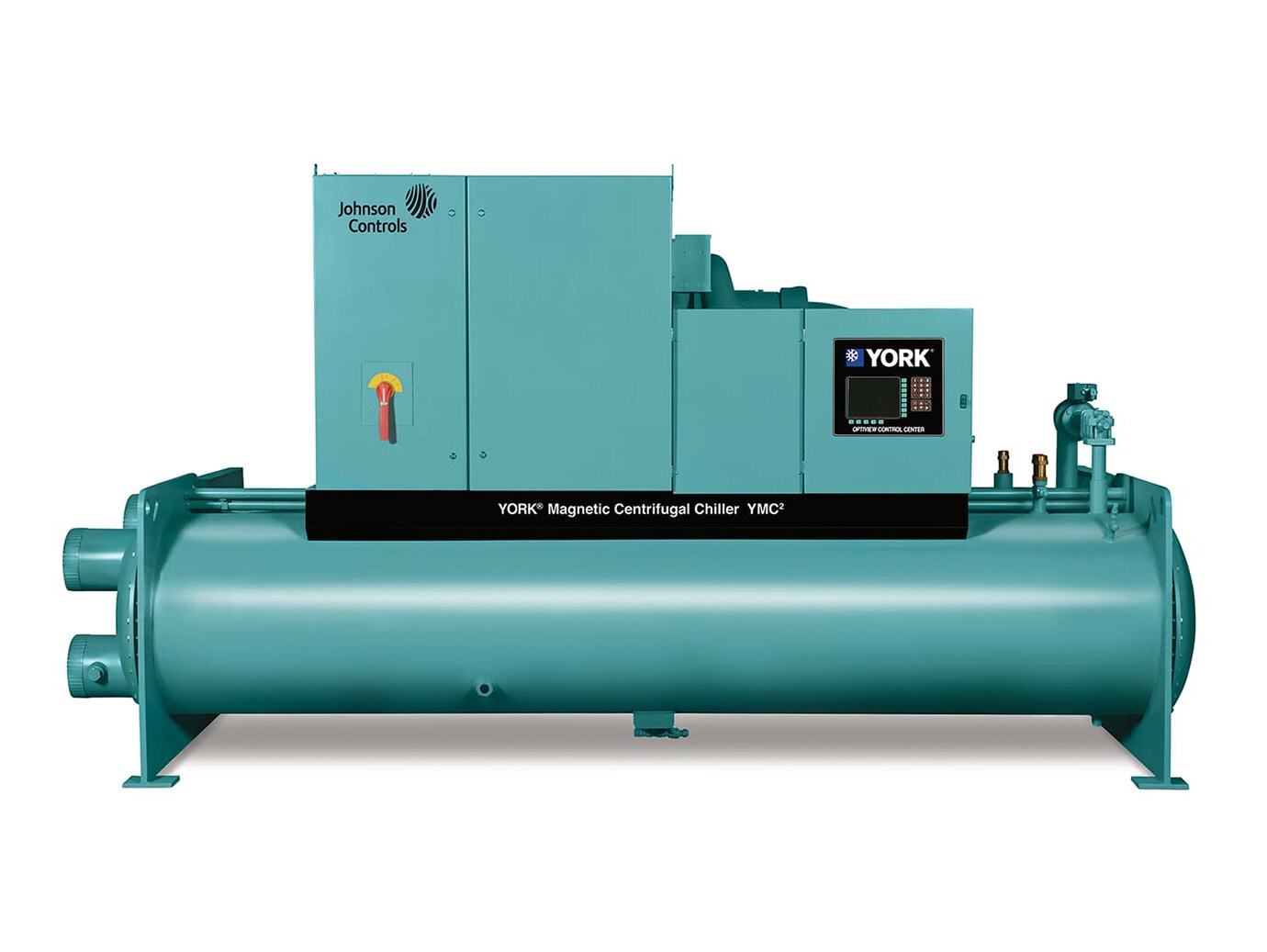

YORK® YMC2 Magnetic Bearing Centrifugal Chiller

165-1,000 TR (580-3,516 kW)

The YORK® YMC2 chiller reduces energy consumption and increases efficiency via advanced design and active magnetic-bearing technology. With years of YORK® chiller advancements and active magnetic-bearing technology, the YMC2 chiller provides healthcare facilities with a lower overall cost of ownership, extraordinary efficiency, versatility, dependability and quiet operation – all in one of the widest-operating, fully integrated, optimized chillers available today

Additional Benefits

- Stable inverted mode cooling operation down to 36 °F (2 °C) entering condenser water temperature

- Fully integrated, lubrication-free and oil-free design

- Exceptional efficiency with below 0.1 kW/ton at part load

- Lower total cost of ownership, competitive first cost, low maintenance and operating costs thanks to fewer moving parts

YORK® YZ Magnetic Bearing Centrifugal Chiller

150-2,020 TR (530-7,104 kW)

Built upon decades of industry-leading chiller expertise, the YORK® YZ Magnetic Bearing Centrifugal Chiller is a revolutionary advancement that challenges everything about conventional chiller design. Its magnetic-bearing driveline offers outstanding reliability for mission-critical applications, with 80% fewer moving parts than traditional oil- or refrigerant-lubricated drivelines. At the same time, the YORK® YZ is also the first chiller fully optimized for ultimate performance with a next-generation, low-GWP refrigerant. Delivering exceptional efficiency and operation, the YORK® YZ is the chiller built to exceed every expectation.

Additional Benefits

- Variable-speed drive, variable-geometry diffuser and magnetic-bearing technology deliver up to 35% annual energy savings versus traditional, fixed-speed, oil-bearing chillers

- Capable of operation with condenser temperatures below the evaporator temperatures, eliminating the need for a water-side economizer, which simplifies the system, requires less mechanical room space and saves money on components, piping, controls and maintenance

- Optimized, single-stage compressor design provides best real-world energy efficiency and the widest operating range at off-design conditions

- Patented falling-film evaporator design reduces refrigerant charge up to 60% and reduces evaporator shell size up to 20%